Gears

Gears

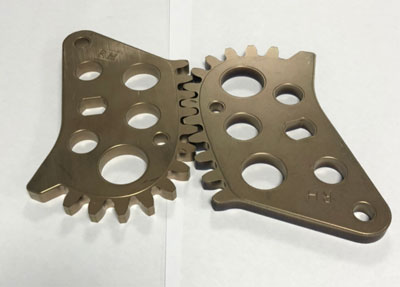

Powdered metal gears have inherent advantages over gears cut by conventional methods. Compared to machining, the powdered metal process is often more efficient in terms of cost, materials, and energy. Gears manufactured from powdered metal have highly accurate tooth profiles, and can incorporate innovative design features to reduce stresses and increase strength. In addition, the natural porosity of powdered metal gears lowers vibration and noise.

Gear Types

- Spur

- Bevel

- Planetary Clusters

- Face Gears

- Multi-Level

- Pinion

- AGMA Class 6 Cluster Gears

- Fine Pitch

Sprockets

Sprockets require precise tooth profiles, high core strength, and exceptional wear characteristics to allow for maintenance-free, low-noise, high-efficiency chain drives. Powdered metal is a proven cost-effective manufacturing process for sprockets, delivering net-shape parts in a wide range of sizes, tooth shapes, and complex geometries with little or no machining. The ability to tailor materials and processes for high-density sprockets leads to optimized weight-to-strength ratios and enhances application possibilities.

Bearings

Self-lubricating sintered bearings deliver high performance under load and offer exceptional wear properties. The porosity of bearings produced through the conventional powdered metal process makes oil impregnation possible, eliminating the need for a supplemental lubrication system. This lifelong lubrication makes sintered bearings a versatile alternative to costly roller bearings.

Custom Structural

Custom Structural

As a net-shape technology, powdered metal is an economical way to manufacture a variety of small structural parts. The powdered metal process forms details on smaller components with the same precision as machining, but uses up to 97% of the raw material, limiting waste to a negligible amount. With low tooling costs, at higher volumes, the savings achieved through this net-shape process grow substantially.

Ratchets

Ratchets

Powdered metal ratchets and pawls are widely used in a variety of industries having application to many markets. Customer specific designs of lock dogs, pawls, and ratchets are used in the manufacture of automotive restraint systems. Other parts such as lever locks and pawl grippers are used in the construction of hand tools.

Flame Arrestors

Flame Arrestors

Powdered metal materials are a popular choice because these highly engineered materials consist of a uniform, interconnected porosity that can be fabricated to allow precise gas flow control while providing a non-shedding, mechanically sound, media to quench the flame front. Powdered metal provides cost effective solutions for high volume devices, especially for applications that require the prevention of a flame front in the event that an intense explosion occurs. Porous sintered metal media can also be formed into net shapes and easily joined to hardware to create unique assemblies.